KNOTT VGB18 braked axle for trailer/carriage 1800kg 1140/1248mm 1700mm 5x112

The braked axle from the KNOTT manufacturer is designed for heavy trailers or flatbeds with a maximum load capacity of 1800 kg for a single axle and 3500 kg for a tandem axle. The mounting hole spacing is 1140/1248 mm, the hub spacing is 1700 mm, which allows for easy installation in a wide range of vehicles. The 5x112 bolt spacing ensures compatibility with most wheels available on the market. The swing arm length is 160 mm, which ensures stability and optimal shock absorption, thus increasing driving safety, even with a full load. Additionally, the axle is equipped with a central cylinder mount, which allows the trailer to be raised and lowered, increasing its functionality in applications requiring precise control of the loading platform position.

Axles are the structural foundation of every trailer, providing its stability, strength and proper cushioning during transport. They are a key element that allows for the safe transport of various loads. Choosing the right axles is important because it affects the safety, driving comfort and durability of the entire transport system. Proper cushioning helps protect the transported goods from damage, and the correct load capacity ensures stability during driving, especially in difficult conditions.

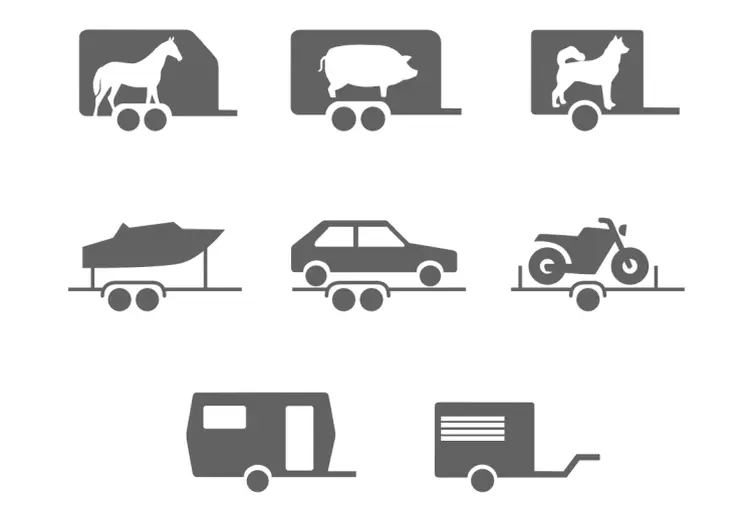

Trailer axles - versatility of use

Trailer axles are distinguished by their versatility, thanks to which they can be used in various types of vehicles, such as cargo trailers, caravans, flatbed trailers, or trailers for transporting animals and equipment. Their universal design allows them to be adapted to various transport conditions, regardless of the type of load being transported. These axles provide stability, safety and driving comfort, which makes them a reliable solution both in everyday use and for more specialized tasks. Thanks to the possibility of installing additional components, such as shock absorbers, their operation can be further optimized, adapting the trailer to individual needs.

Independent suspension and maintenance-free

The KNOTT rubber torsion suspension sets standards in durability and maintenance-free operation. Based on a solid, uniform axle with rubber rollers, it is characterized by exceptional resistance to wear. This design eliminates the need for regular inspections and lubrication, which significantly reduces operating costs. Thanks to the use of high-quality materials, the KNOTT suspension maintains its properties even in difficult weather conditions, ensuring long-term and trouble-free operation.

Driving comfort thanks to the advanced suspension system

The suspension based on a square axle profile with rubber rollers provides effective shock absorption in all conditions. Its innovative design effectively absorbs shocks by compressing and stretching the rubber when driving over uneven surfaces, minimizing the impact of uneven surfaces on the trailer and load. This simple, yet effective operating principle guarantees a smooth ride, minimizes the risk of damage to the load and increases travel comfort, making KNOTT axles the ideal choice for demanding trailer users.

Advanced brake design and easy maintenance

KNOTT axles are equipped with high-quality brake systems, in which precisely matched brake drums play a key role, ensuring optimal contact with the shoes and guaranteeing effective, even braking. The Backmat brake used in size 200x50 not only ensures reliable operation even in difficult conditions, but thanks to the automatic reversing system it significantly facilitates maneuvering when driving backwards, eliminating the need to manually release the brake. The design enabling easy service and replacement, combined with full compliance with European safety standards, makes the KNOTT brake system the ideal choice for demanding trailer users who value reliability, safety and comfort of use.

Maintenance-free bearings and easy assembly

The axles feature advanced compact bearings as an integral part of their reliable system. These precision-engineered components combine high durability with ease of maintenance, offering optimum performance in a variety of operating conditions. These bearings are factory-lubricated and sealed, eliminating the need for regular maintenance and adjustments. By combining durability, maintenance-free operation and reliability, compact bearings significantly contribute to the overall safety and reliability of the axle.

Optimum protection against corrosion

Advanced anti-corrosion protection guarantees long-term durability and aesthetic appearance. The axle profile is subjected to a hot-dip galvanizing process, which provides comprehensive protection against rust and weather conditions, even in the most demanding conditions. At the same time, the brake hub is protected with a high-quality KTL coating (cataphoresis), known for its excellent adhesion and resistance to mechanical damage. This two-stage surface protection method not only significantly extends the life of the axle, but also minimizes the need for maintenance, which translates into lower operating costs and reliability for many years of use.