AL-KO EURO braked axle for trailer/carriage 1800kg 1300mm 1800mm 5x112

The braked axle from the AL-KO manufacturer is designed for heavy trailers and flatbeds, offering a maximum load capacity of 1800 kg with a single axle and 3500 kg with a tandem axle. The mounting hole spacing is 1300 mm, and the hub spacing is 1800 mm, which allows for easy installation in a wide range of vehicles. The 5x112 bolt spacing ensures compatibility with a wide range of wheels available on the market . The swing arm length is 175 mm, which guarantees stability and optimal shock absorption, thus increasing driving safety, even with a full load. Additionally, the axle is equipped with a shock absorber mount, which additionally increases the comfort of use and stability while traveling.

Axles are the structural foundation of every trailer, providing its stability, strength and proper cushioning during transport. They are a key element that allows for the safe transport of various loads. Choosing the right axles is important because it affects the safety, driving comfort and durability of the entire transport system. Proper cushioning helps protect the transported goods from damage, and the correct load capacity ensures stability during driving, especially in difficult conditions.

Trailer axles - versatility of use

Trailer axles are distinguished by their versatility, thanks to which they can be used in various types of vehicles, such as cargo trailers, caravans, flatbed trailers, or trailers for transporting animals and equipment. Their universal design allows them to be adapted to various transport conditions, regardless of the type of load being transported. These axles provide stability, safety and driving comfort, which makes them a reliable solution both in everyday use and for more specialized tasks. Thanks to the possibility of installing additional components, such as shock absorbers, their operation can be further optimized, adapting the trailer to individual needs.

Independent suspension and maintenance-free

Thanks to the independent suspension, each wheel is damped separately, which means that road irregularities only affect the side they are on. This system is maintenance-free and does not require maintenance, which allows users to save on servicing and maintenance costs. Additionally, the axle design eliminates the risk of damage to the wheel arch and other components due to excessive rotation of the swingarm, even under heavy load.

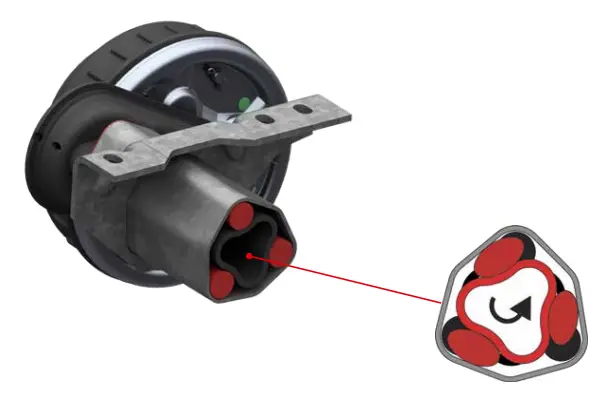

Driving comfort thanks to the advanced suspension system

Modern axles, such as those with the AL-KO hexagonal suspension system with rubber rollers, offer significantly improved ride comfort. Large deflection arrows and softer damping make the trailer ride smoother and vibrations are effectively reduced. Compared to standard steering axle systems, this suspension allows for more effective damping of road irregularities, which increases user comfort and safety.

Advanced brake design and easy maintenance

The advanced brake design includes axles with brake drums equipped with cooling fins, which provide better heat dissipation, which increases the efficiency of the braking system. Additionally, the axles and braking mechanisms are bolted, which allows easy removal of the entire brake mechanism after unscrewing the screws, which significantly facilitates maintenance. Special meshing also allows changing the position of the brake cable outlet, adapting it to the individual needs of the user, which increases the functionality of the system.

Maintenance-free bearings and easy assembly

The axles are equipped with double angular contact ball bearings (compact bearings) that are designed for 250,000 km of operation. They are lubricated for life with a special water-displacing grease, which prevents the ingress of dirt. Additional safeguards, such as double hub seals, protect the mechanisms from water and dirt. Thanks to the standardized tightening torque, axle assembly is quick and easy.

Optimum protection against corrosion

The axle profile, frame and housing of the overrun devices are protected against corrosion by hot-dip galvanizing, which guarantees protection for a period of 10 years. Steel elements that require high precision are subjected to galvanizing, providing 5 years of protection against corrosion. For parts with the highest precision, electrogalvanizing is used, which protects them for 4 years. These various galvanizing methods effectively protect all components, ensuring their long durability and resistance to external factors.